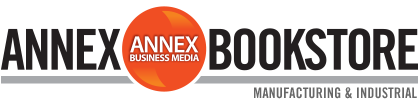

Industrial Air Quality and Ventilation

$401.85

In the field of industrial ventilation and air quality, a lack of adequate analysis for aerodynamic processes, as well as a shortage of properly equipped computer facilities, has forced specialists to rely on an empirical approach to find answers in the past. Commonly based on crude models, practical data, or countertypes, the answers often offered have been imprecise.

Summarizing the results of the authors’ research conducted over the past 40 years, Industrial Air Quality and Ventilation: Controlling Dust Emissions examines air injection in granular material streams and defines the closed hood capacity widely used in the mechanical reprocessing of minerals. This book introduces a methodological approach (dynamic theory) that broadens the range of granular materials, including inter-heated material. It considers the mechanisms of ejecting air in different variations from uniform air motion processes in closed chutes to the forming of accelerated air streams in a free particles flow. It also provides the scientific basics of calculation for local exhaust ventilation dust production (aspiration), and enables readers to accurately apply these results to the mechanical processing of various materials.

• Describes the engineering methods for calculating the amounts of aspirated air for various industries and technological units

• Assists in developing new environmentally clean and competitive advanced technologies and equipment for the processing of granular materials

• Proposes new technical solutions that are more sanitary and require less energy and water consumption

• Looks at specific industry examples of localization of release

Industrial Air Quality and Ventilation: Controlling Dust Emissions proposes low power consumption-based technical solutions and outlines more accurate methods of calculating recommended performance. Richly illustrated with practical suggestions and techniques, the text includes real-world applications in the field of aerodynamic processes within gravitational fluxes of granular material, and encourages the development of new environmentally clean and competitive advanced technologies and equipment for the processing of granular materials.

Features:

* Presents theoretical and practical recommendations for designing and implementing local exhaust ventilation systems

* Examines and contrasts the different modes of ventilation-closed chutes, suction hoods, dust-collection bags, etc.

* Addresses ventilation issues for various industries (mining, smelting, chemicals, building materials, etc.)

* Considers the aerodynamics of different particles, and how best to mitigate dust from their manufacture/processing (grains, cereals, flour, iron ore, crushed stone)

* Proposes new technical solutions that require less energy and water consumption, and are more sanitary